(英文)] Masaki KITAZUME (Tokyo Institute of Technology,Tokyo,Japan)

(Tokyo Institute of Technology,Tokyo,Japan)

deep mixing method,earthquake,liquefaction,disaster mitigation

备注

在日本的陆地和海洋工程建设中,软质冲积粘土地基十分常见,这种地基的柔软及高压缩性容易引发沉降和失效。砂质土壤具有相对较好的抗压缩性能,但在地震作用下,松散和饱和状态的砂质土壤也会发生液化。日本每年发生许多地震,如1995年阪神地震及2011年日本东北大地震都引发了人道主义危机,导致了巨大的经济损失。发生在松散和饱和砂层中的液化效应,会引起基础设施的巨大损害。多年来,液化控制对减轻地震灾害的重要性一直被强调,开发了很多基于各种原理的地基加固技术以减轻地震灾害。其中,20世纪70年代,日本开发的深层搅拌法(DMN)作为原位水泥稳定技术之一,经常被用来改进粘性和砂质土壤。近期,网格类型的DMM还被用以防止的土壤液化,其中,网格由稳定的墙柱组成,在地震过程中通过限制土壤颗粒的运动以防止超孔隙压力的产生。改良方法的效果首先在1995年的阪神地震中被验证合理。本文简要介绍了深层搅拌法在防震减灾中的一些应用。

:In Japan,soft alluvial clay ground has frequently encountered in on land and marine constructions.The ground is so soft and compressible large settlement and failure can occur.Sandy soil has relatively better properties for compressibility,but liquefaction might happen during earthquakes in the case of loose and saturated condition.Many earthquakes occur each year in Japan,in which the 1995 Hyogoken-Nambu earthquake and the 2011 Tōhoku earthquake induced both a humanitarian crisis and massive economic impacts.As liquefaction which occurs in a loose and saturated sand layer,inducing quite large damages of infrastructures,the importance of liquefaction mitigation has been emphasized to minimize earthquake disasters for many years.Many kinds of ground improvement techniques based on various principles have been developed for earthquake disaster mitigation.Among them,the deep mixing method(DMM),one of the in-situ cement stabilization techniques,was developed in 1970s in Japan and has been often applied to improvement of clayey and sandy soils.Recently,the grid type of DMM has also been applied to prevent liquefaction,where the grid of stabilized column walls function to restrict generation of excessive pore pressure by confining the soil particle movement during earthquakes.The improvement effect of the method was first evaluated in the 1995 Hyogoken-Nambu earthquake.In this paper,some applications of deep mixing method to earthquake disaster mitigation are briefly introduced.

Introduction

Soft alluvial clay ground is wildly distributed in Japan, and many structures have to be built on it Obviously, this ground has a deadly defect, liquidation, which will destroy the stability of the structures and even cause the buildings to collapse under the seismic action.In fact,port and harbor facilities at Kobe Port were heavily damaged in the 1995 Hyogoken-Nambu earthquake,where gravity type of sea revetments displaced a couple of meters towards sea together with large ground settlement at backfill yard.Table 1 shows the amount of damage to port facilities caused by strong earthquake(Noda,1991),and demonstrates quite large difference between conditions and without liquefaction.According to the Table 1,when liquefaction takes place,the amount of earthquake disaster is about 20 to 50 times larger than that of without liquefaction.This highlights the importance of liquefaction mitigation to minimize earthquake disasters

There are many kinds of soil stabilization techniques developed and available in Japan for countermeasure of stability,ground deformation and liquefaction.Among these techniques,the deep mixing method,one of the in-situ cement stabilization techniques,was developed in 1970s in Japan and has been frequently applied to improvement of clayey and sandy soils(Kitazume,Terashi,2013).Recently,the grid type of DMM has been often applied to prevent liquefaction,where the grid of stabilized column walls function to restrict generation of excessive pore pressure by confining the soil particle movement during earthquakes.The improvement effect of the method was first evaluated in the 1995 Hyogoken-Nambu earthquake.In this paper,some applications of deep mixing method to earthquake disaster mitigation are briefly introduced.

1 Deep Mixing Method

2 Concluding remarks

In this paper,some applications of Deep Mixing Method to earthquake disaster mitigation are briefly introduced.This paper at first emphasizes the importance of liquefaction mitigation to minimize earthquake disaster.The applications introduced in this paper clearly reveals the high applicability of the deep mixing method to earthquake disaster mitigation.The method has been applied successfully to various sites and improvement purposes in the past and expected to be developed further for more various sites and improvement purposes in the future.

1.1 Outline of the MethodDeep Mixing Method(DMM),an in-situ admixture stabilization technique using cement and/or lime as a binder,has been applied in many construction projects for various improvement purposes(Kitazume,Terashi,2013).DMM was put into practice in Japan in the middle of 1970s to improve soft marine deposits,and was spread into China,South East Asia,and recently to the other part of the world.Two decades of practice has made equipment improved,binders changed,and applications diversified.Lime is replaced with cement in Japan.The special machines used to stabilize soft soil are basically composed of several mixing shafts and blades,and a binder-supplying system.In one operation,a column of treated soil is constructed in a ground.Through a series of construction steps,any arbitrary shape of improved mass(such as block,wall and grid types)can be formed in the ground.For liquefaction mitigation,the block and grid types of DMM

have been applied.

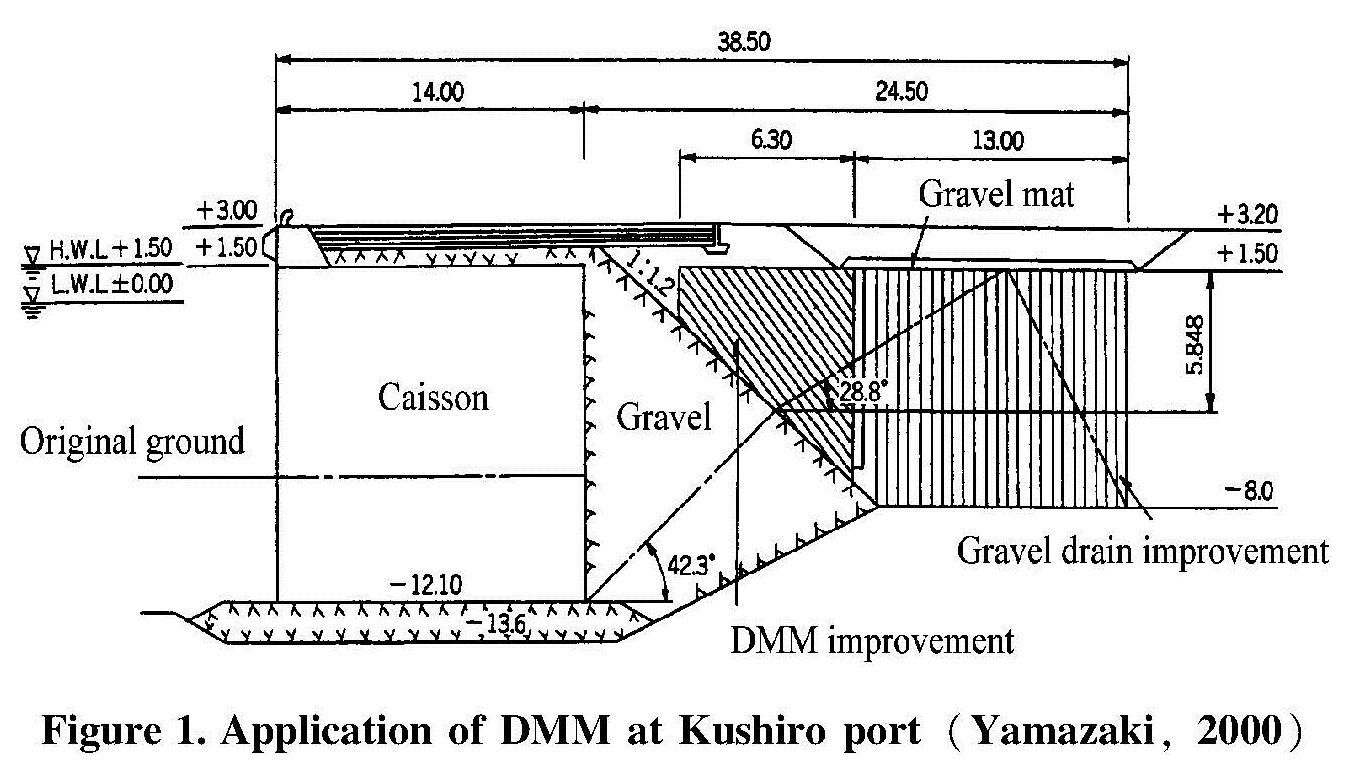

1.2 Application of the Block Type DMM for Sea RevetmentFigure 1 shows an application at Kushiro port for liquefaction mitigation of backfill,where sandy ground was stabilized by a block type improvement with 100% improvement area ratio.The ratio of the improved soil area to the whole site area.The design field strength qu,was 100 kPa,which was considerably low level compared with that for clay soil improvement.The revetment was subjected to the 1994 Toho-Oki earthquake,which caused huge damages with liquefaction and cracks at unimproved area.However,due to the ground improvement,negligible damage took place at the revetment,which has confirmed the high applicability of DMM for earthquake disaster mitigation(Yamazaki,2000).

1.3 Application of the Grid Type DMM for BuildingDMM was applied to foundation of a building at the Kobe Port,where sandy ground was improved by a grid type improvement to prevent excessive pore water pressure generation during earthquakes.A 14-story building

located on Meriken Wharf in Kobe was experienced the 1995 Hyogoken-Nambu earthquake.The soil profile at the site consisted of 10~12 m of soft reclaimed sand and gravel layers over the seabed.The seabed soil consisted of alternating layers of clay,sand and gravel.The building was supported by cast-in-place reinforced concrete piles with a diameter of 2.5 m extending to dense diluvial sand and gravel at a depth of 33 m.Its section and plan diagrams are shown in Figure 2.A grid type improvement was applied to prevent liquefaction in the upper loose fill.The improvement area ratio was approximately 20%.The unconfined compressive strength of the improved soil after about six weeks curing was 4~6 MPa(Tokimatsu et al,1996; Suzuki et al,1996; Namikawa et al,2007).

Figure3a shows the damage of quay wall near the building after the earthquake.The concrete caisson type quay walls on the west,south and east displaced horizontally by 1 m,2 m,and 0.6 m respectively and settled by 0.5 m,0.6 m and 0.3 m.Sand boils and ground fissures were observed at the ground surface.In the building,however,there was no crack at the surface of the improved ground as shown in Figure 3b.The head of the cast-in-place piles supporting the building was found to be intact.Moreover,negligible differential settlement was observed on the first floor of the building.These have indicated that the cement stabilization improvement could mitigate the damage to pile foundation and superstructure.

1.4 Application of the Grid Type DMM for EmbankmentYodo River flows from Lake Biwa to Osaka Bay through Osaka City.Due to the Hyogoken-Nambu Earthquake in January 1995,the river dike was heavily damaged for the length of 1.8 km because of slope failure due to ground liquefaction(Kamon,1996).A representative cross section of the damaged dike is shown in Figure 4a.The top portion of the river dike sank down about 3 m.The damaged dike had to be restored very quickly,because there was a risk of flooding during the rainy season which usually commenced in June.The ground condition at the site is shown in Figure 4b.The ground consisted of a sandy layer and a clayey layer.As the SPT N-value of the sandy layer was smaller than 10,the liquefaction might take place again in earthquake attack in the future.Because there were many residential houses in the neighborhood along the river dike,it was necessary to avoid noise and vibratory problems during the construction.This was one of the reasons why the deep mixing method was applied.The cross section of the improved ground is shown in Figure 4c,where grid type improvement

was applied to prevent the liquefaction of the ground and to improve the stability of river embankment.The grid of the stabilized soil columns was about 5 m by 5.4 m.The design strength of the stabilized column,qu was 500 kPa.Assuming the strength ratio of the field stabilized soil and laboratory stabilized soil,quf/qul was assumed to be 0.25 in the design,and 90 or 100 kg/m3 of blast furnace slag cement type B were mixed to achieve the design strength for the sandy layer and clay layer respectively.

1.5 Other applications of the Grid Type DMMSoon after the aftermath of the 2011 Tohoku earthquake and tsunami,the Cement Deep Mixing(CDM)Association,the Dry Jet Mixing(DJM)Association and Chemical Grouting Co.Ltd.conducted field surveys in the Tohoku and Kanto areas to investigate any deformation and damage in the deep mixing improved ground and the performance of the improved grounds.Though few slight deformations were found in some grounds,as a whole no severe deformation and damage was found in the improved ground and superstructures even they were subjected to quite large seismic force(Kitazume,2012; Tokunaga et al,2015).Here,two applications in the field surveys are briefly introduced.

1.5.1 Road embankmentThe road embankment at Soga,Chiba Prefecture,was improved by the grid type deep mixing method for liquefaction prevention.The original ground beneath the embankment contains large amount of fine sand to the depth of -7 m,which was anticipated to be highly liquefied due to earthquake motion.The improved ground has about 5.6 m in width,6.0 m in height,and the improvement area ratio is 50%,and whose unconfined compressive strength,qu is 200 kN/m2(Figure 5a).No damage was found in the embankment and the improved ground is shown in Figure 5b,even subjected to the seismic force of 5.0 upper in Japanese Magnitude-Shindo(seismic intensity scale).As contrast,Figure 5c shows heavy damage on road without improvement located in the neighborhood due to liquefaction.

1.5.2 River embankmentThe foundation for the river embankment in Chiba Prefecture was improved by the grid type DM method as shown in Figure 6a,where the width and height of the improved ground were 21.0 m and 21.0 m respectively The improvement area ratio and the design

strength were 50.6% and the design unconfined compressive strength,quck of 600 kN/m2 respectively.No damage was found in the embankment and the improved ground,as shown in Figure 6b.

- KITAZUME M,TERASHI M.2013.The Deep Mixing Method.CRC Press[M].Abingdon:Taylor & Francis Group,434.

- KITAZUME M.2012.Soil mixing performance in the 2011 Tohoku earthquake[J].The Magazine of the Deep Foundations Institute,77-78.

- NAMIKAWA T,KOSEKI J,SUZUKI Y.2007.Finite element analysis of lattice-shaped ground improvement by cement-mixing for liquefaction mitigation[J].Soils and Foundations,47(3):559-576.

- NODA S.1991.Waterfront development and liquefaction[J].Journal of the Japanese Society of Soil Mechanics and Foundation Engineering,‘Tsuchi-to-Kiso'.Japanese Geotechnical Society,39(2):1-4.

- SUZUKI Y,SAITOH S,ONIMARU S,et al.1996.Grid-shaped stabilized ground improved by deep cement mixing method against liquefaction for a building foundation[J].Journal of the Japanese Society of Soil Mechanics and Foundation Engineering,‘Tsuchi-to-Kiso',Japanese Geotechnical Society,44(3):46-48.

- TOKIMATSU K,MIZUNO H,KAKURAI M.1996.Building damage associated with geotechnical problems[J].Soils and Foundations,52(5):219-234.

- TOKUNAGA S,KITAZUME M,MORIKAWA Y,et al.2015.Performance of cement deep mixing method in 2011 Tohoku earthquake[J].Proc of the Deep Mixing 2015,1071-1080.

- YAMAZAKI H.2000.Current and trend of ground improvement techniques for liquefaction prevention for port facilities(2)-Effectiveness and trend of techniques[J].Japan Society of Civil Engineers Magazine,Civil Engineering,85:60-62.