基金项目:国家重点研发计划(2018YFC0809400); 山东省自然科学基金面上项目(ZR2020ME247).

(1.山东电力工程咨询院有限公司,山东 济南 250100; 2.哈尔滨工业大学 结构工程灾变与控制教育部重点实验室,黑龙江 哈尔滨 150090; 3.哈尔滨工业大学(威海)土木工程系,山东 威海 264209; 4.中国地震局工程力学研究所 地震工程与工程振动重点实验室,黑龙江 哈尔滨 150080)

(1.Shandong Electric Power Engineering Consulting Institute Co.,Ltd.,Jinan 250100,Shandong,China)(2.Ministry-of-Education Key Laboratory of Structural Dynamic Behavior and Control,Harbin Institute of Technology,Harbin 150090,Heilongjiang,China)(3.Department of Civil Engineering,Harbin Institute of Technology in Weihai,Weihai 264209,Shandong,China)(4.Key Laboratory of Earthquake Engineering and Engineering Vibration,Institute of Engineering Mechanics,China Earthquake Administration,Harbin 150080,Heilongjiang,China)

ultra-high voltage transmission tower; hanging joint; bearing capacity; full-scale experiment; FEM simulation; force-transferring nut

DOI: 10.20015/j.cnki.ISSN1000-0666.2024.0002

备注

基金项目:国家重点研发计划(2018YFC0809400); 山东省自然科学基金面上项目(ZR2020ME247).

引言

我国资源的地域分布显著不均,西部地区蕴含着丰富的能源与电力资源,实施“西电东送”等工程是平衡我国资源布局的客观要求,也是促进经济共同发展的重大战略举措。特高压输电线路作为高负荷电能输送的载体,是保证国计民生和生产生活的重要生命线工程(钟岱辉等,2020)。安全可靠的输电塔线结构是保障我国能源通道畅通的重要一环,电力命脉的可靠运行是保障经济建设和人民生活的大事。但输电线路事故仍时有发生,如1999年中国台湾集集地震导致28条345 kV超高压输电线路受损,输电中断,造成了巨大的直接经济损失,由此引发的间接经济损失更是难以估算(陈绍蕃,2010); 2008年汶川8.0级地震造成3 322条10 kV及以上输电线路受损停运,造成直接经济损失106亿元,恢复重建费用高达346亿元(张大长等,2009); 2013年,国网辽宁省220 kV金吴线发生导线挂线节点根部断裂事故,高压导线落地断电。

近年来,国内外学者在输电塔线结构体系优化、抗震抗风性能等方面开展了较多的研究(王飞,2020; 白杰等,2013; 张毅等,2019; 张丽娟等,2021a),研究多集中在整体抗震性能方面(董利虎,宋丹青,2021; 田利等; 2018; 拾峰,周安清,2015; 李士锋,袁清泉,2014; 魏文晖等,2022; 钟岱辉等,2020; 黄帅等,2014)。挂线节点是联系输电塔与导线的重要构件,是将导线荷载传递给输电塔结构的关键节点,其损坏将直接引发导线掉落、输电塔结构冲击振荡等问题。对于特高压输电线路而言,挂线节点所受到的导线自重、风、地震、导线张力等荷载更大,受力形式更加复杂,应该引起高度重视。一些学者对输电塔节点进行了研究,如姜常胜等(2017)研究了使用双独立挂点的悬垂线夹结构受力性能,分析了导线扭动状态下挂点的动弯应力及疲劳性能; 张毅等(2019)试验研究了不等边角钢交叉斜材对输电塔节点承载力的影响,并基于能量法及有限单元法提出了不等边角钢交叉斜材承载力理论计算方法; Soh等(2000)采用屈服线模型对钢管塔节点的极限承载力进行了简化理论分析; Knigt和Santhakumar(1993)对输电塔的节段模型进行了足尺试验,证明节点刚度对输电塔节段力学性能影响明显; 余世策等(2004)对钢管塔节点极限承载力进行了试验与理论研究,结果表明节点局部区域进入塑性阶段并不代表其丧失承载力。在有限元建模与仿真方面,Kitipornchai(1996)研究表明,当输电塔所受荷载较为复杂时,采用梁单元模拟得到的结果比空间桁架单元更加准确。

目前针对输电塔线结构体系的研究仍主要集中在塔身节点理论分析、缩尺节点模型性能试验以及有限元仿真等方面,对输电线路足尺挂线节点的力学性能研究较少。因此,开展特高压输电塔足尺挂线节点在复杂受力下的失效模式及承载力性能提升策略研究方面具有理论意义和工程价值。本文通过对某特高压输电塔足尺挂线节点进行拟静力加载试验,研究挂线节点在复杂荷载作用下的承载力及其失效模式,并在张丽娟(2021b)研究的基础上,提出了一种新型双侧挂板协同受力的钢管输电塔挂点结构,通过加载试验与有限元建模仿真,对比分析挂线节点单侧受力和双侧受力情况下的承载力及失效机理差异,给出了挂线节点承载力提升的具体措施和建议。

1 钢管输电塔挂线节点基本信息

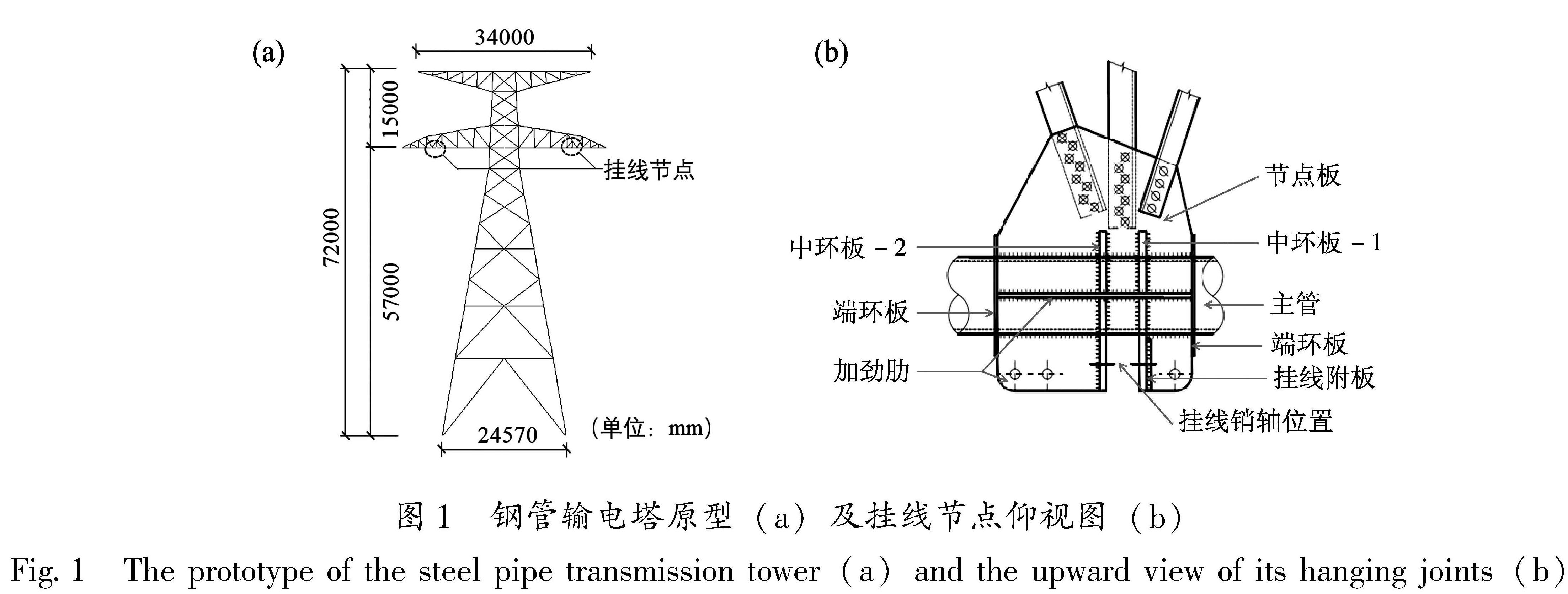

本文所建立的挂线节点来源于某特高压钢管输电铁塔结构,输电塔轮廓尺寸及挂线节点如图1a所示。该挂线节点由主管、端环板、中环板、加劲肋、销轴以及节点板等部件组成,其仰视效果如图1b所示,节点主要几何参数见表1。

图1 钢管输电塔原型(a)及挂线节点仰视图(b)

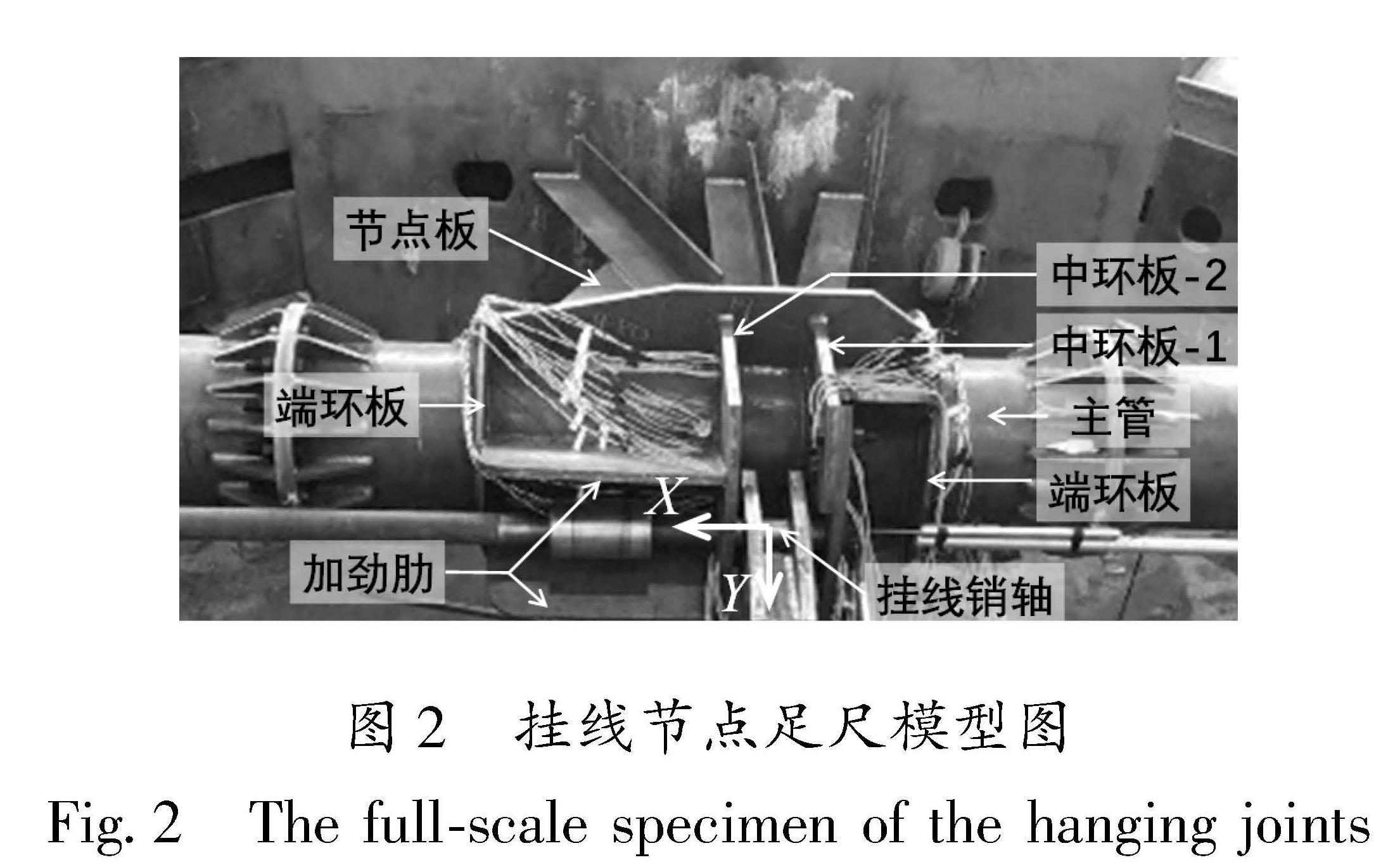

Fig.1 The prototype of the steel pipe transmission tower(a)and the upward view of its hanging joints(b)挂线节点选用Q345钢材,足尺实验节点试件如图2所示。挂线节点所选用钢材弹性模量为203 GPa,泊松比为0.3。通过对钢管、钢板的标准实验件进行静力拉伸实验获得了材料的基本力学性能。其中,钢管材料和钢板材料的屈服强度分别为420 MPa和390 MPa,屈服应变分别为2.0‰和1.9‰,极限强度分别为620 MPa和559 MPa。

2 钢管输电塔挂线节点承载力试验

在实际工程中,挂线节点主要承受导线的自重、水平张力以及由地震、风荷载引起的附加动力荷载作用。因此,在工程设计中需要考虑挂线节点在上述作用下的最不利荷载组合。本文重点研究特高压钢管输电塔挂线节点在最不利荷载组合下的力学性能及失效模式。

2.1 挂线节点模型介绍本试验对象包括单侧受力型挂线节点(JD-1)和新型双侧受力型挂线节点(JD-2)两类试件。现有挂线节点销轴一般只包含一个受力螺母,该螺母通常只会使挂线节点的单侧挂线板承受荷载,而当荷载作用反向时又转变为另一侧挂线板单独受力,不利于导线荷载的传递。在上述挂线节点基础上在销轴内新增一个传力螺母,可以实现两侧挂线板协同受力,提高挂线节点的承载能力。

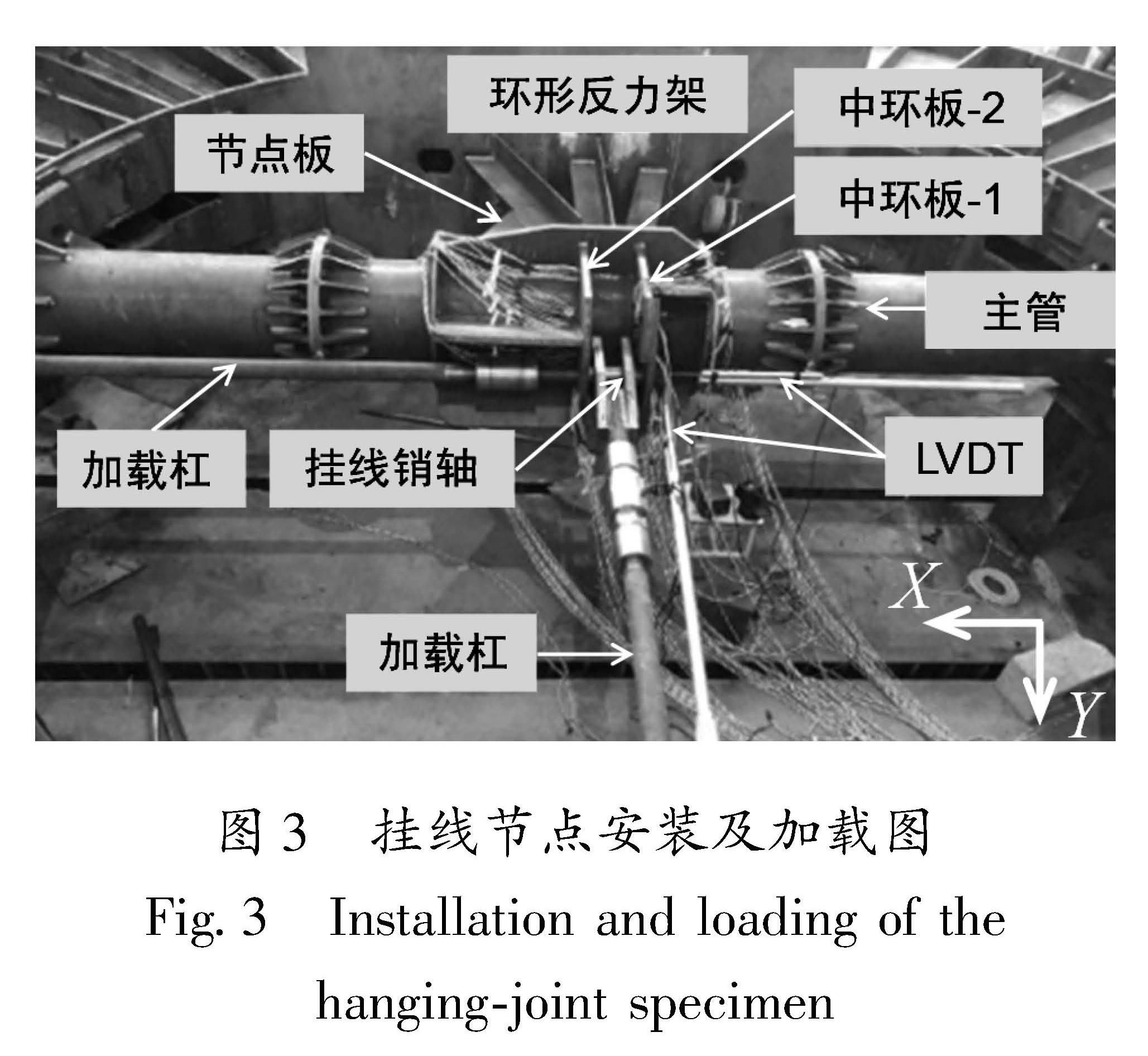

挂线节点力学性能试验在哈尔滨工业大学土木工程学院教育部重点试验室进行。试验时先将节点模型安装在刚性环反力架中,该反力装置不仅具有足够的刚度以保证自身不发生较大变形,还可以使挂线节点试件的加载过程更加合理,传力路径明确,具体节点安装如图3所示。

2.2 试验方案与数据采集由于该挂线节点同时受到两个方向的作用力,即平行销轴方向(X方向)和垂直销轴方向(Y方向)。模型安装时,在沿平行于销轴方向,将拉杆与销轴通过螺栓连接后穿出刚性环反力架,并在拉杆端部串联液压作动器和力传感器,通过反向传力的方式对节点区域施加拉力荷载; 在垂直于销轴方向,则通过特制的连接板套过销轴后施加拉力荷载,挂线节点沿X、Y方向进行多级协同比例加载。

第1阶段:在所加荷载分别达到挂线节点X、Y方向设计荷载P1、P2之前,按照各自的设计荷载值进行等比例协同加载,沿X、Y方向每级荷载的增长幅值分别为0.1P1和0.1P2; 第2阶段:达到挂线节点的设计荷载后,沿X、Y方向每级荷载的增长幅值分别调整为0.05P1和0.05P2,直至分别达到1.5P1和1.5P2; 第3阶段:沿挂线节点X、Y方向继续按照每级荷载增幅分别为0.02P1和0.02P2不断提高荷载,直至节点发生破坏后停止加载。

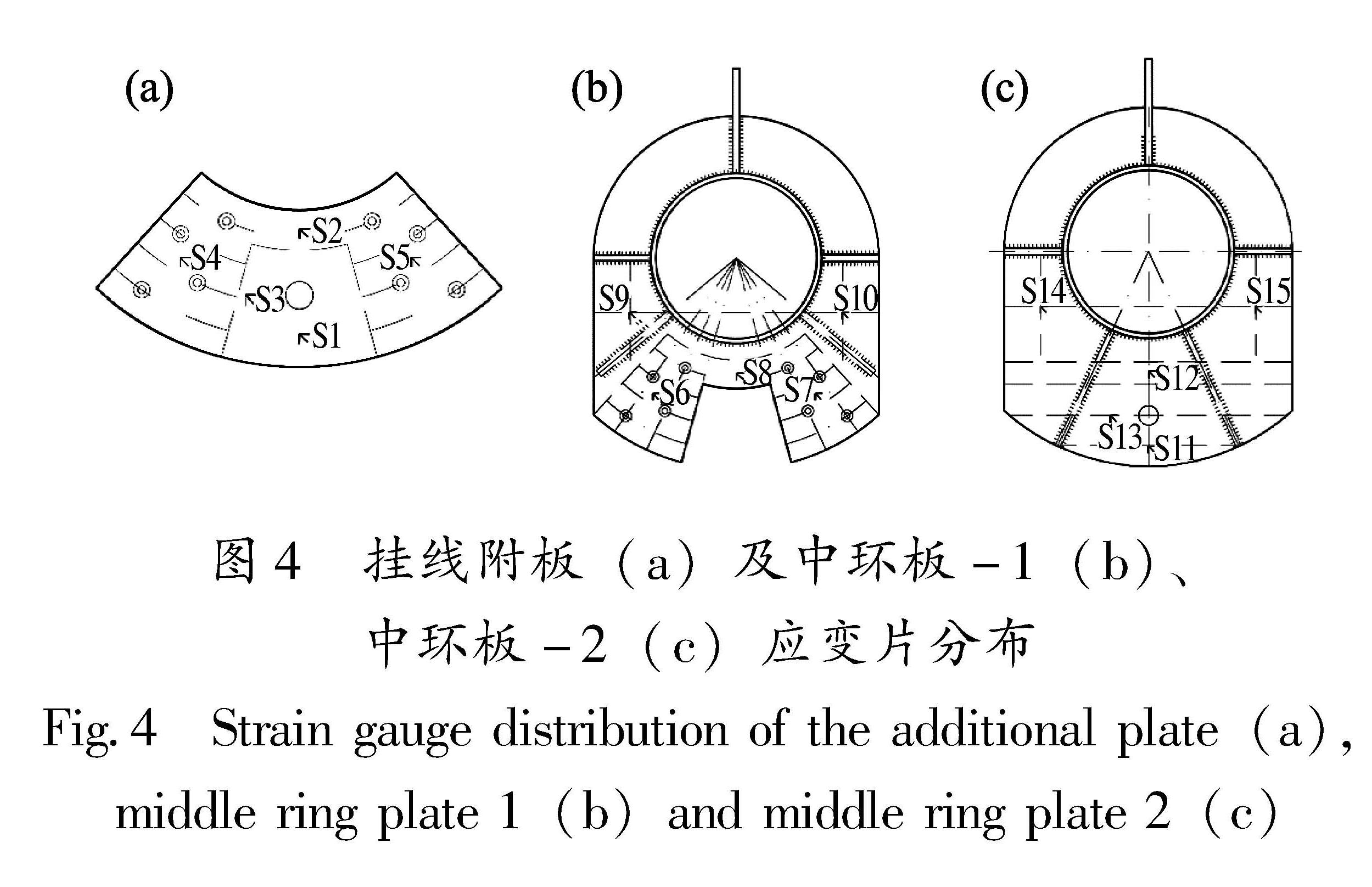

试验测量和观察的内容主要包括:①应变测量:在挂线节点的主要受力板件上布置22个应变花,获得各主要受力部位的应变分布及发展,应变花布置如图4所示。②变形测量:在与挂线附板连接的螺母上布设LVDT位移计(X方向、Y方向各1个),测量加载过程中节点沿X、Y方向的变形量。③加载力测量:通过在液压千斤顶端部串联的力传感器获得加载力的大小。④破坏模式:观察加载过程中挂线节点主要部件的变形特点,对比JD-1和JD-2的失效模式差异。

3 挂线节点有限元建模

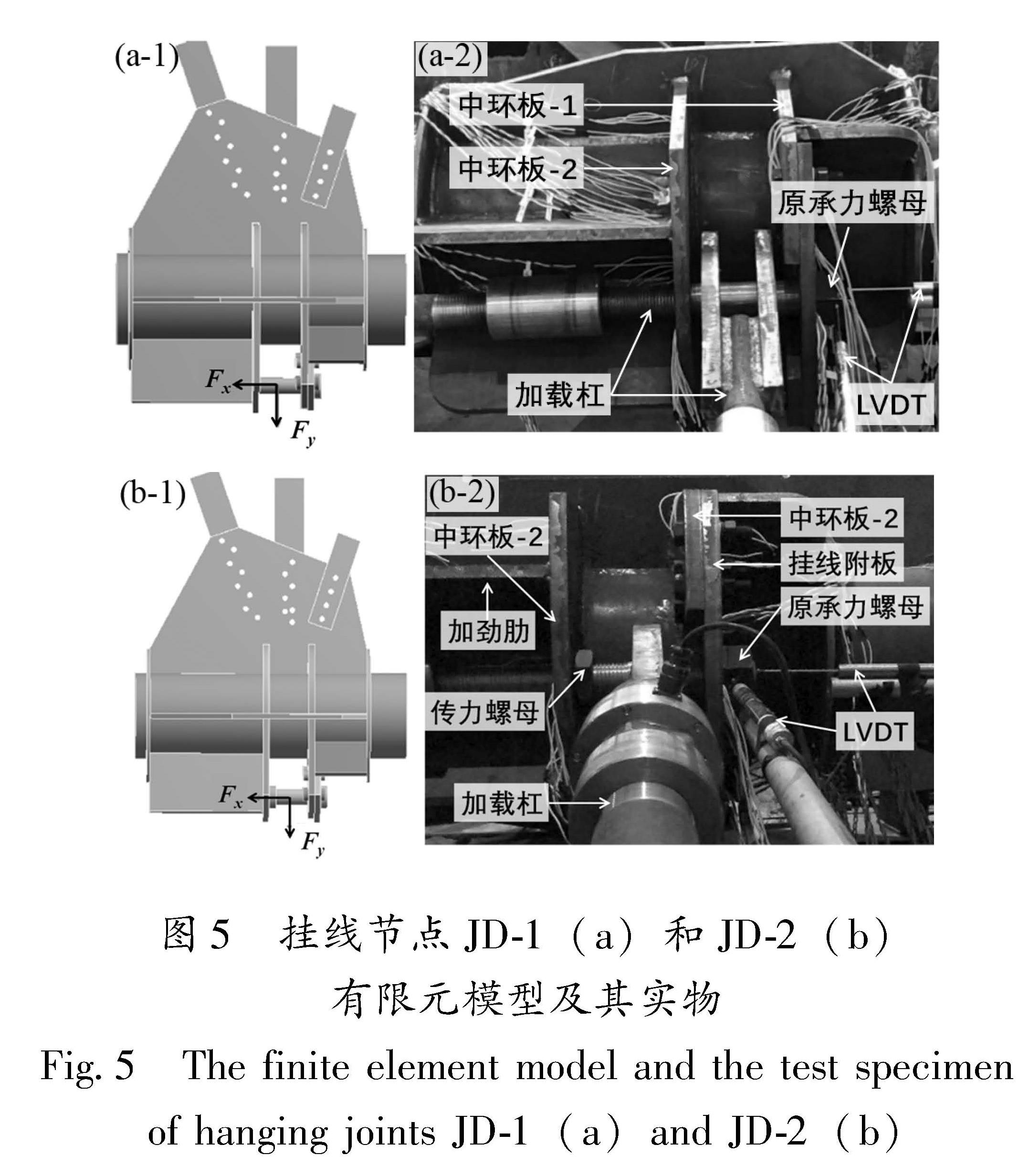

采用ANSYS Workbench有限元平台对本文研究的两类挂线节点进行建模和分析。挂线节点和螺栓均采用实体单元Solid 186建模,使用六面体单元进行网格划分; 在节点板、加劲肋与环板交界处采用Sizing选项对网格进行细化处理,JD-1和JD-2的有限元模型及实物如图5所示。

图5 挂线节点JD-1(a)和JD-2(b)有限元模型及其实物

Fig.5 The finite element model and the test specimenof hanging joints JD-1(a)and JD-2(b)在JD-1处的连接中,通常先将销轴穿过2个中环板上的孔洞,之后在挂线附板侧面通过单个内径为63 mm的螺母将销轴固定,此时沿挂线节点X方向的作用力仅由右侧板件(即中环板-1)承受,沿Y方向的作用力则由左、右两侧板件共同承受。在JD-2处的连接中,通过在挂线节点两侧板件内增加一个六边形传力螺母,螺母内径为63 mm、边长为75 mm,该螺母可以使沿挂线节点X方向的作用力同时由中环板-1、中环板-2承受,还可以通过调整传力螺母在销轴上的位置来改变中环板-2对节点承载力和刚度的贡献,简便有效。

4 结果及分析

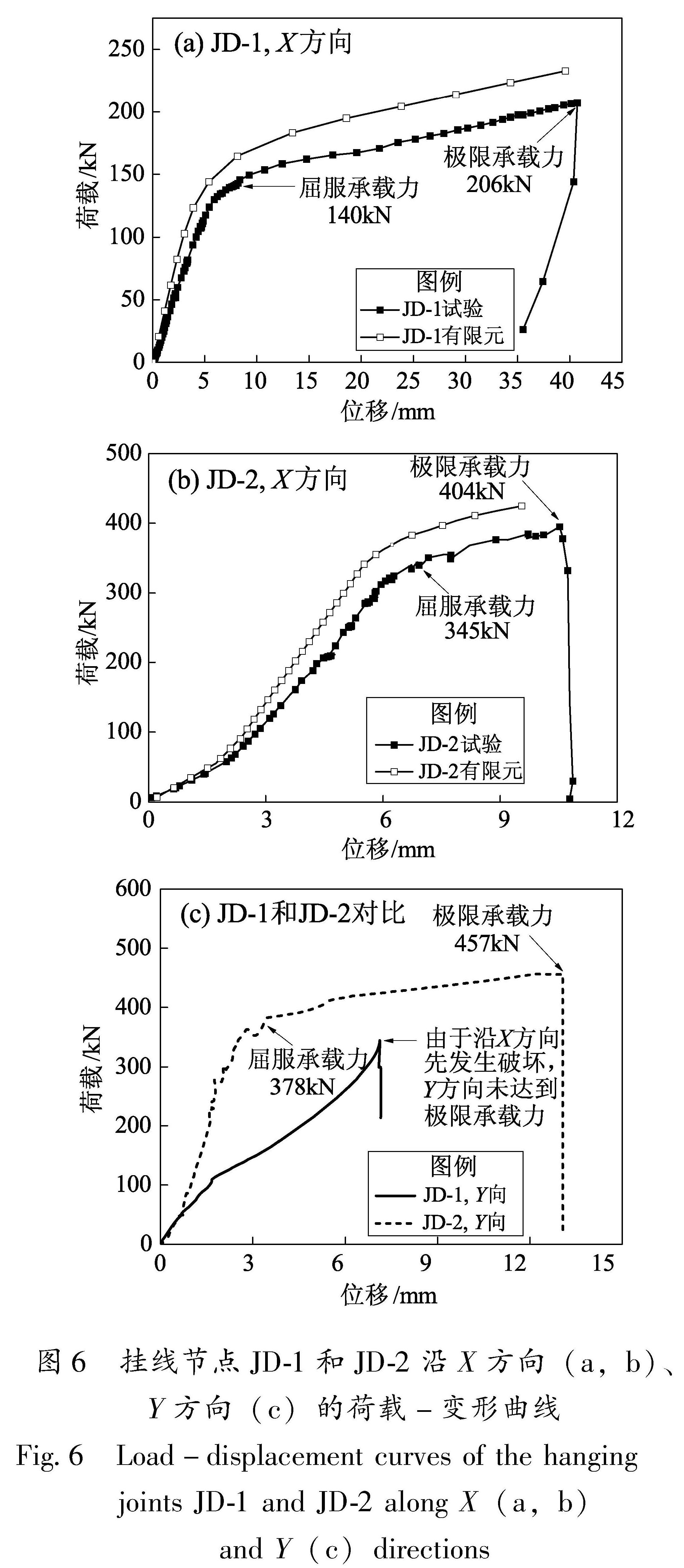

4.1 挂线节点承载力分析JD-1和JD-2沿X方向、Y方向的荷载-变形曲线如图6所示。为了验证有限元模型的正确性,挂线节点在荷载作用下的有限元结果也在图6中一并给出。通过对荷载-变形曲线的弹性阶段与塑性阶段进行分段等效线性拟合,可以得到挂线节点的等效屈服承载力。

图6 挂线节点JD-1和JD-2沿X方向(a,b)、Y方向(c)的荷载-变形曲线

Fig.6 Load-displacement curves of the hangingjoints JD-1 and JD-2 along X(a,b)and Y(c)directions由图6可知,挂线节点在X方向的承载力低于Y方向,这是由于挂线节点沿X方向的承载力主要靠中环板的面外弯曲变形承担,而沿Y方向的承载力则由中环板面内变形承担。从图6c可以看出,在双向同步加载过程中,JD-1首先沿X方向发生破坏,而此时并未达到Y向极限承载力。根据图2挂线节点的构造特点可知,沿X轴负向加载时,中环板-2将作为主要受力板件承受荷载作用。由于中环板-2为完整板件,其上不存在缺口,且其左侧的两个加劲肋的间距较小,挂线节点的承载力明显高于沿X正向加载情况。[HJ2mm]挂线节点的失效模式主要受沿X轴正向荷载的影响,因此本文重点关注挂线节点沿X方向的性能和失效机理。

从图6a可知,JD-1在沿销轴方向的荷载达到130 kN时开始进入屈服状态。随着荷载的增加,JD-1的中环板-1变形明显增加; 当荷载达到206 kN时,JD-1的中环板-1发生破坏,节点丧失整体承载能力。由图6b可知,JD-2在荷载达到340 kN时逐渐进入屈服状态,当荷载达到404 kN时,节点丧失整体承载力。试验结果表明,JD-1沿X方向的受拉屈服承载力和极限承载力分别为140 kN和206 kN。根据计算结果得出,JD-1在最不利荷载组合下沿X方向、Y方向的受力分别为283 kN和280 kN,JD-1不能满足承载力要求,而改进后的JD-2节点沿X方向的受拉屈服承载力和极限承载力分别为345 kN和404 kN,沿Y方向的屈服承载力为378 kN,满足承载力要求。

利用有限元模型计算得到的节点JD-1和JD-2

沿X方向的屈服承载力分别为155 kN和370 kN,有限元模型计算得到的屈服承载力和刚度均略高于试验值,其原因主要包括:①试验中挂线节点与刚环反力架之间还存在连接管件,这些管件在加载过程中会产生少量形变,导致节点整体刚度下降; ②双向协同加载方式很难保证作用力始终严格处于同一水平面内,这使得节点可能产生面外变形而导致承载力有所降低。在有限元模型中,挂线节点采用的是理想边界条件,且可以保证面内同步加载,故JD-1和JD-2的数值结果与试验结果存在一定偏差,分别约为10.7%和7.2%,但总体规律一致,可用于后续模拟和分析。

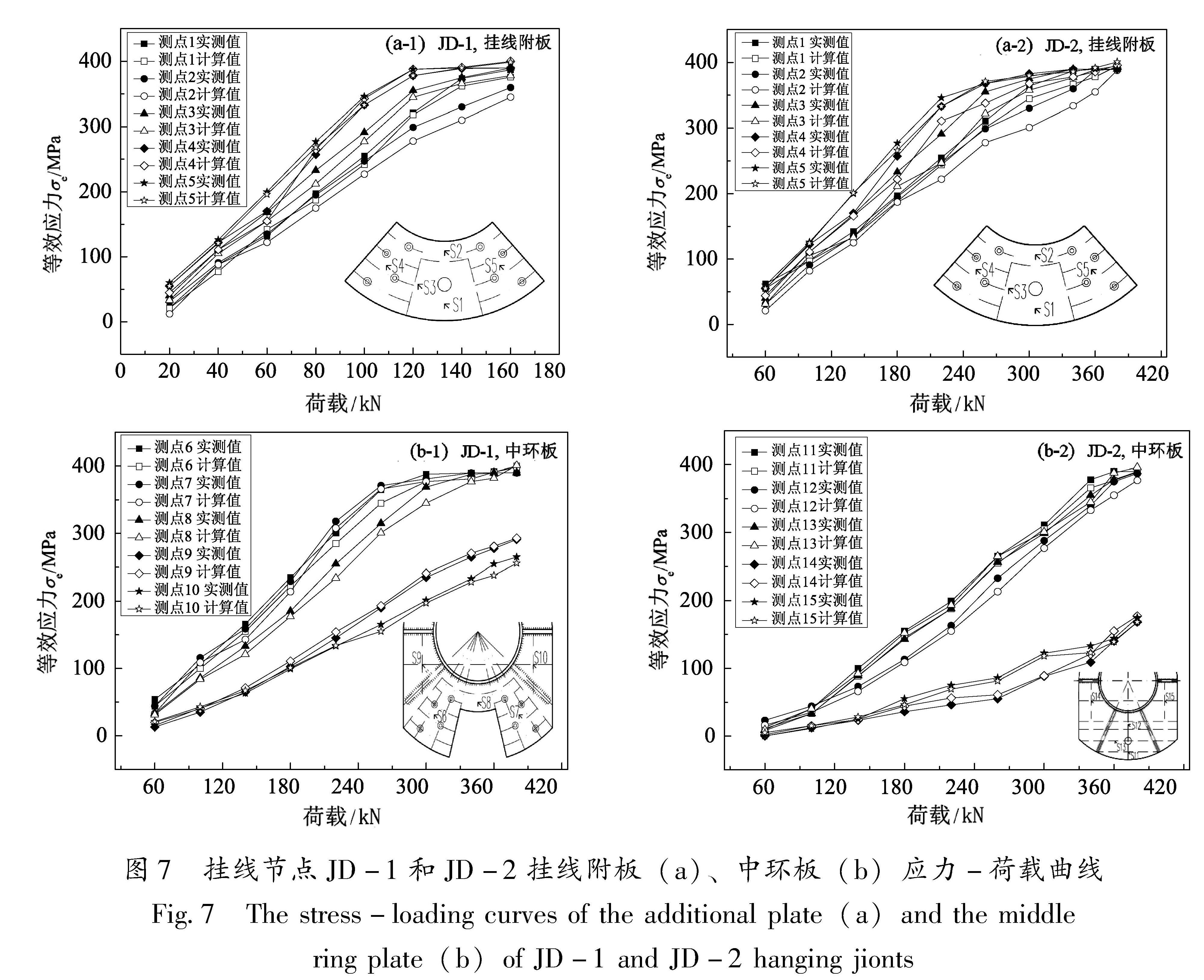

4.2 挂线节点关键部位应力-荷载变化规律挂线附板和中环板是输电塔挂线节点的重要组成部分,在导线荷载作用下,挂线附板首先将作用力依次传递至中环板和主管,之后传递给塔身和基础。挂线附板和中环板的刚度和承载能力将影响整个挂线节点的力学性能。JD-1和JD-2的挂线附板在整个加载过程中的应力-荷载曲线如图7a所示,中环板-1和中环板-2在屈服阶段的应力-荷载曲线如图7b所示。

图7 挂线节点JD-1和JD-2挂线附板(a)、中环板(b)应力-荷载曲线

Fig.7 The stress-loading curves of the additional plate(a)and the middlering plate(b)of JD-1 and JD-2 hanging joints图7给出了挂线附板、中环板等效应力的有限元计算结果。从图7a-1可以看出,JD-1在挂线附板测点4、5处的应力水平明显高于其它测点位置,这两处测点在X方向荷载达到130 kN时进入屈服状态; 当X方向荷载达到140 kN时,除测点2未进入屈服状态外,其余测点均达到屈服应力,表明挂线附板整体进入屈服状态。由图7b-1可知,当外荷载达到130 kN时,中环板-1上的测点6、7处的应力水平接近屈服状态,测点8的应力水平低于测点6、7,中环板-1与矩形加劲肋夹角以外区域内的测点9、10应力水平更低,在整个加载过程中均未发生屈服。

从图7a-2可知,对于JD-2,当沿X方向荷载达到300 kN时,挂线附板上的测点4、5以及中环板-1上的测点6、7和8处的应力水平接近屈服状态,测点9、10处的应力水平较低。当沿X方向荷载增加至380 kN时,挂线附板所有测点均进入屈服状态,挂线附板发生弯曲屈服。从图7b-2可以发现,与JD-1不同,由于受到传力螺母的传力影响,JD-2的中环板-2上的整体应力水平比较高,靠近挂线孔处测点11、12和13处的应力水平相当,并在荷载达到340 kN后上述测点逐渐进入屈服状态,表明中环板-2已经与中环板-1、挂线附板协同受力,明显提高了节点刚度和承载力,传力螺母实现了双侧挂线板共同受力的目的。

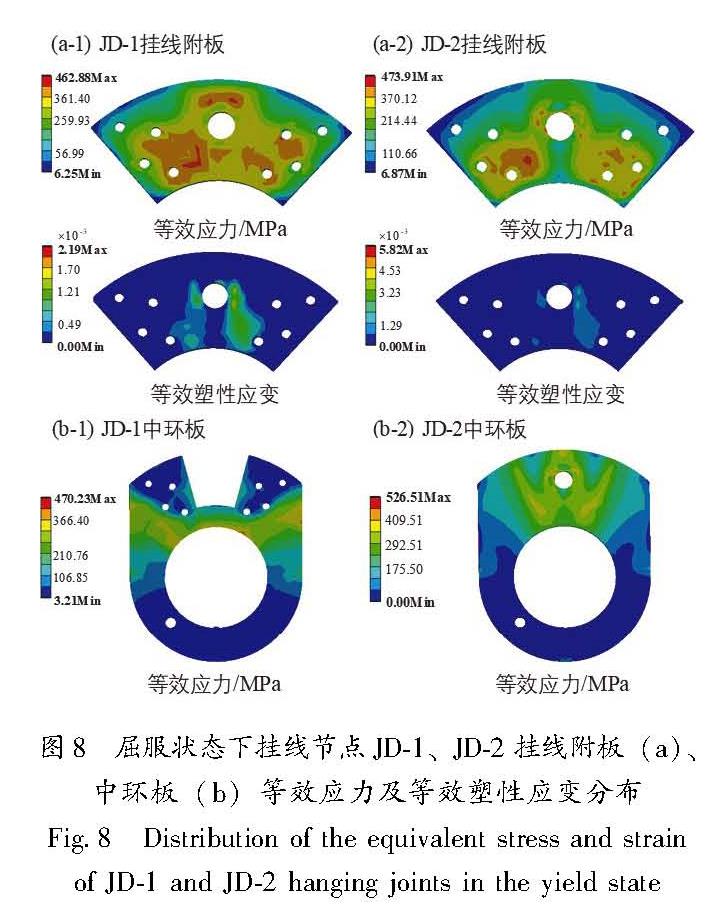

4.3 挂线节点屈服状态等效应力、应变分布规律图8为挂线节点JD-1和JD-2在达到屈服状态时挂线附板、中环板-1和中环板-2的等效应力和等效塑性应变分布云图。从图8a-1、b-1可以看出,由于挂线附板在荷载作用下的弯曲效应,销轴孔与该挂线附板螺栓连接孔之间区域内的应力水平较高,同时螺栓孔周围存在局部高幅应力区。对于中环板-1,其在主管矩形加劲肋和挂线附板螺栓连接孔之间区域的应力水平较高。

通过对比图8a-2、b-2可以发现,JD-2的挂线附板和中环板-1的应力分布规律与JD-1比较接近,但高应力区域面积明显减小; 中环板-1在挂线板螺栓孔与主管矩形加劲肋之间的区域应力较高,说明挂线附板端部区域为高应力区,容易先发生屈服。与此同时,双侧受力型挂线节点的中环板-2在挂线孔附近区域应力水平较高,并逐渐向远处扩散,这表明传力螺母已经将部分沿销轴轴向的导线荷载有效传递给了另一侧中环板,从而有效分担原有挂线附板上的荷载作用。

5 挂线节点失效模式及性能提升效果分析[BT)]

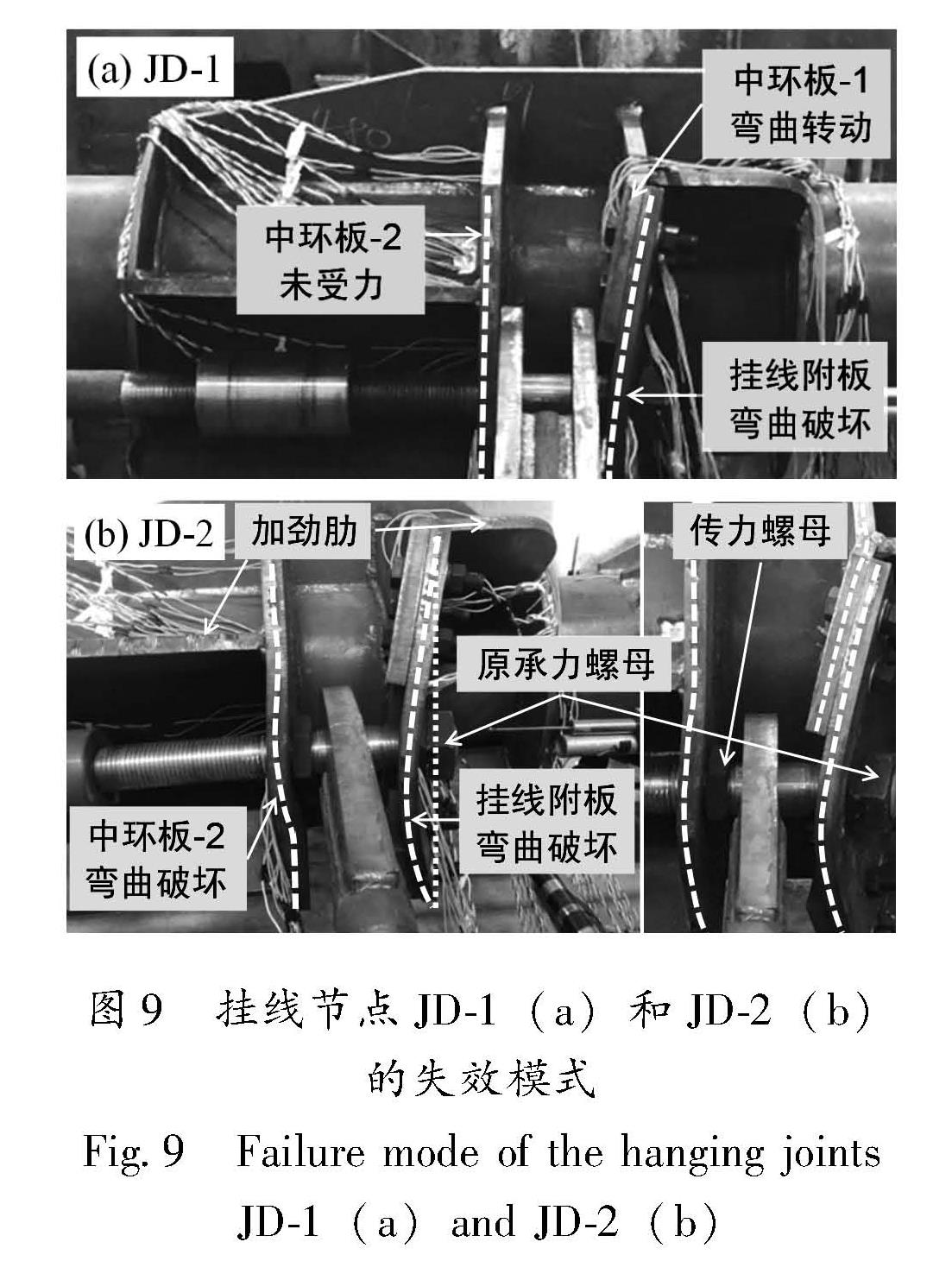

5.1 挂线节点失效模式对比随着荷载的不断增大,挂线节点JD-1、JD-2均进入第二刚度区段,其在导线荷载作用下的失效模式如图9所示。从图中可以发现,在沿销轴X方向荷载作用下,JD-1的挂线附板发生弯曲破坏,而中环板-1与挂线附板重叠部分发生整体旋转并引发加劲肋根部焊缝开裂。因此,在单侧板件受力情况下,中环板-1将承担全部沿X方向的导线荷载,且由于中环板-1上还设有缺口(主要用于销轴安装和更换),使得挂线节点的刚度明显降低,变形增大,这对承受巨大导线荷载作用的特高压输电塔结构非常不利。

同JD-1相比,JD-2在中环板-2的右侧安装了一个传力螺母,该螺母与中环板-2之间的预留空隙为1.5 mm。此时,JD-2的失效模式则变为挂线附板和中环板-2同时发生弯曲破坏,而中环板-1的破坏模式与JD-1相似,这表明在双侧板件受力情况下,中环板-1和中环板-2可以共同承担沿X方向的导线荷载,从而使得节点的屈服承载力显著提升。另外,由于中环板-2上没有挂线缺口,且其位于主管两加劲肋之间的有效弯曲段长度也低于中环板-1,因此其面外抗弯刚度更高,上述因素也是导致图6b中双侧受力型挂线节点的屈服承载力和刚度都大大高于图6a中单侧受力型挂线节点的主要原因。

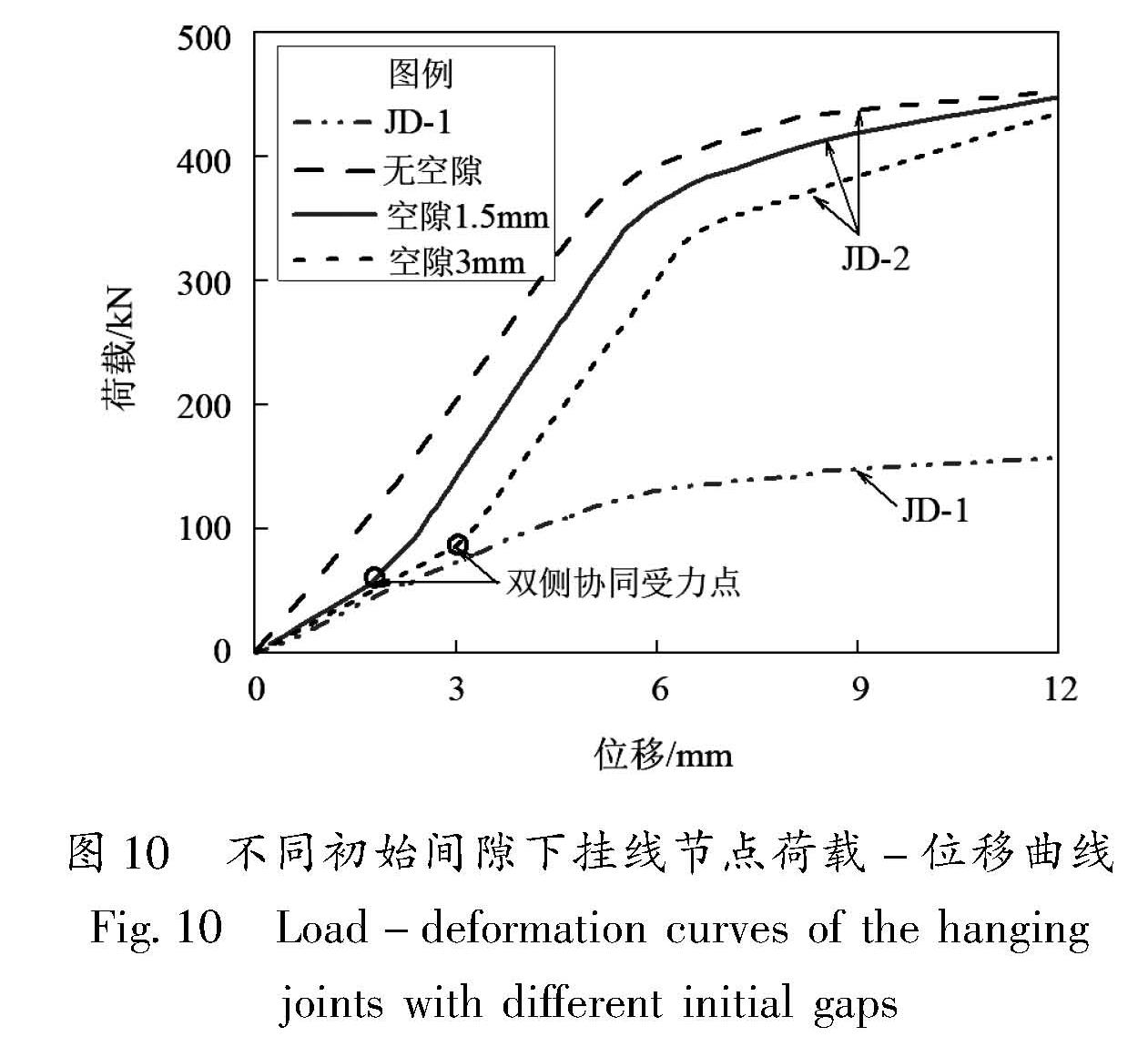

5.2 双侧受力型挂线节点对承载力提升规律分析前文分析表明,双侧受力型模式对节点承载力的提升作用非常显著,节点传力形式更加合理。基于实体有限元模型,本文重点研究了传力螺母与中环板-2之间初始间隙对双侧受力型挂线节点承载力的影响规律。不同初始间隙下双侧受力型挂线节点荷载-位移曲线如图 10所示。从图中可以发现,同单侧受力型挂点相比,双侧受力型挂点的屈服承载力和极限承载力均有不同程度提升,双侧挂板协同受力点可以直接从荷载-位移曲线中读取,在传力螺母发挥作用以前,节点荷载主要由中环板-1和挂线附板承担,当初始缝隙消失时,中环板-2将参与协同受力,节点刚度增加。从上可见,初始间隙越大,挂线节点双侧环板的协同受力越晚,这将对挂线节点的整体承载力和刚度产生不利影响。

图 10 不同初始间隙下挂线节点荷载-位移曲线

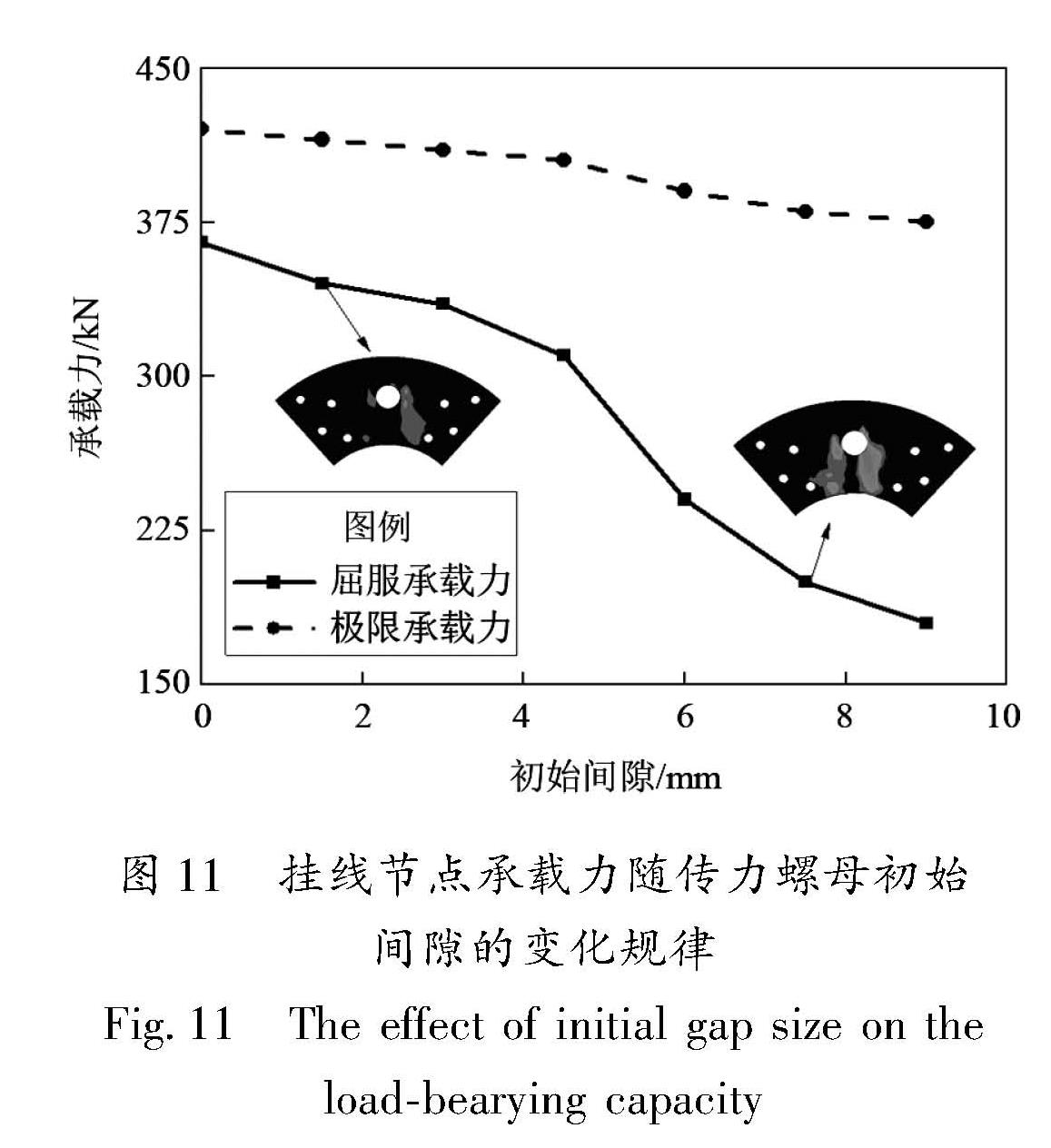

Fig.10 Load-deformation curves of the hangingjoints with different initial gaps从图 11所示的挂线节点承载力随传力螺母初始间隙的变化规律可以看出,挂线节点屈服承载力随着初始间隙的增大而有所下降,屈服点向右下方移动,节点屈服后的刚度有所提高,这是双侧挂板协同受力的时刻后延导致的; 挂线节点的极限承载力随传力螺母初始间隙的增大略有下降,但总体变化幅度较小,这主要是由于极限承载力取决于双侧挂板均发生失效时的出力之和,在板厚一定的情况下,中环板-1和中环板-2的极限承载力之和基本保持不变。

尽管传力螺母与挂线板-2之间的初始间隙对挂线节点的极限承载力影响较小,但其屈服承载力随初始间隙的增加下降较快。由于节点设计一般为弹性设计,因此建议传力螺母的初始间隙不能过大,同时考虑挂线销轴需要转动的因素,本文建议传力螺母与挂线板-2之间的初始间隙为2~4 mm。因此,通过将单侧挂板受力形式合理地转化为双侧挂板受力形式,可以有效提高挂线节点的安全性,这将对特高压输电塔挂线节点的优化提供重要的参考和指导。

6 结论

针对特高压钢管输电塔挂线节点在复杂荷载下的力学性能,本文提出了双侧挂线板协同受力的改进措施,并通过足尺挂线节点承载力试验与有限元分析,对比研究了挂线节点在单侧挂线板受力、双侧挂线板受力情况下的应力、应变分布规律和失效模式,并提出了挂线节点承载力提升的具体建议。主要结论如下:

(1)挂线节点沿垂直销轴方向的承载力高于平行销轴方向,应重点关注平行销轴方向的节点刚度和承载力。当仅由单侧挂线板承受导线荷载时,节点的屈服承载力和刚度均明显偏低; 安装传力螺母后,左、右两侧挂线板将协同受力,挂线节点的刚度和承载力也得到明显提升,屈服承载力可提高一倍以上。

(2)单侧受力型挂点的失效模式表现为挂线附板和同侧中环板整体弯曲破坏,双侧受力型挂点的失效模式表现为两侧挂线板均发生弯曲破坏,且挂线板上的应力分布趋于均匀,传力螺母作用明显。

(3)传力螺母与挂线板之间的初始间隙对挂线节点的屈服承载力和刚度影响较大,但对节点极限承载力影响较小,考虑到节点弹性设计和销轴转动因素,建议该初始间隙设置为2~4 mm为宜。

- 白杰,谢强,薛松涛.2013.特高压单回路酒杯型输电塔线耦联体系振动台试验研究[J].工程力学,30(4):472-480.

- Bai J,Xie Q,Xue S T.2013.Shaking table test on UHV single circuit cup type transmission tower-line coupling system[J].Engineering Mechanics,30(4):472-480.(in Chinese)

- 陈绍蕃.2010.塔架压杆的稳定承载力[J].西安建筑科技大学学报(自然科学版),42(3):305-314.

- Chen S F.2010.Buckling resistance of compression members in tower structures[J].Journal of Xian University of Architecture & Technology(Natural Science Edition),42(3):305-314.(in Chinese)

- 董利虎,宋丹青.2021.输电塔-线体系地震响应分析方法研究进展[J].水资源与水工程学报,32(2):146-151.

- Dong L H,Song D Q.2021.Research progress on seismic response analysis methods of transmission tower-line system[J].Journal of Water Resources and Water Engineering,32(2):146-151.(in Chinese)

- 黄帅,汪俊龙,王舟.2014.输电塔随机地震反应分析及可靠度计算[J].三峡大学学报(自然科学版),36(5):84-87.

- Huang S,Wang J L,Wang Z.2014.Random seismic response analysis and reliability calculation of power transmission towers[J].Journal of China Three Gorges University(Natural Sciences),36(5):84-87.(in Chinese)

- 姜常胜,马世恩,郑维刚.2017.输电杆塔双独立挂点悬垂线夹结构存在问题的探讨[J].东北电力技术,38(11):57-59.

- Jiang C S,Ma S E,Zheng W G.2017.Discussion on problems of transmission tower of double independent hanging point in suspension clamp[J].Northeast Electric Power Technology,38(11):57-59.(in Chinese)

- 李士锋,袁清泉.2014.典型输电塔的地震响应参数分析[J].四川建筑科学研究,40(3):180-182.

- Li S F,Yuan Q Q.2014.Analysis of seismic response parameters of a typical transmission tower[J].Sichuan Building Science,40(3):180-182.(in Chinese)

- 拾峰,周安清.2015.高烈度震区输电塔的地震响应研究[J].电力安全技术,17(9):35-28.

- Shi F,Zhou A Q.2015.Seismic response study of transmission towers in high-intensity seismic areas[J].Electric Safety Technology,17(9):35-28.(in Chinese)

- 田利,刘俊才,潘海洋,等.2018.近断层下输电塔-线体系振动台试验研究[J].土木工程学报,51(5):127-132.

- Tian L,Liu J C,Pan H Y,et al.2018.Research on shaking table test of transmission tower-line system under near-fault earthquake[J].China Civil Engineering Journal,51(5):127-132.(in Chinese)

- 王飞.2020.特高压输电线路杆塔结构抗震性能研究[D].哈尔滨:中国地震局工程力学研究所.

- Wang F.2020.Study on seismic performance of UHV transmission line tower structure[D].Harbin:Institute of Engineering Mechanics,China Earthquake Administration.(in Chinese)

- 魏文晖,黄功伟,徐辅中,等.2022.输电塔线体系在摇摆地震动作用下的动力稳定性分析[J].振动与冲击,41(4):55-61.

- Wei W H,Huang G W,Xu F Z,et al.2022.Analysis of dynamic stability of a transmission tower-line system under tilt ground motion[J].Journal of Vibration and Shock,41(4):55-61.(in Chinese)

- 余世策,孙炳楠,叶尹,等.2004.高耸钢管塔结点极限承载力的试验研究与理论分析[J].工程力学,3(21):155-161.

- Yu S C,Sun B N,Ye Y,et al.Experimental study and theoretical analysis of ultimate strength for steel tubular joint of tall towers[J].Engineering Mechanics,3(21):155-161.(in Chinese)

- 张大长,赵文伯,刘明源.2009.5?12汶川地震中电力设施震害情况及成因分析[J].南京工业大学学报(自然科学版),31(1):44-48.

- Zhang D C,Zhao W B,Liu M Y.2009.Analysis seismic disaster damage cases and their causes of electric power equipment in 5?12 Wenchuan earthquake[J].Journal of Nanjing Tech University(Natural Science Edition),31(1):44-48.(in Chinese)

- 张丽娟,李素超,何西伟,等.2021a.环形加劲肋对大直径相贯钢管节点承载力与失效模式影响研究[J].工业建筑,51(3):104-109.

- Zhang L J,Li S C,He X W,et al.2021a.Study on effects of stiffening rings on bearing capacity and failure modes of large-diameter steel tube joints[J].Industrial Construction,51(3):104-109.(in Chinese)

- 张丽娟,王志远,徐再根,等.2021b.一种双侧挂板协同受力的特高压钢管塔导线挂点:CN214013834U[P].2021-08-20.

- Zhang L J,Wang Z Y,Xu Z G,et al.2021b.A kind of double-side hanging plate synergistic force UHV steel pipe tower wire hanging point:CN214013834U[P].2021-08-20.(in Chinese)

- 张毅,李正良,刘红军,等.2019.特高压输电塔不等边角钢交叉斜材的承载力[J].华南理工大学学报(自然科学版),47(7):19-31.

- Zhang Y,Li Z L,Liu H J,et al.2019.Study on the stability bearing capacity of unequal angle cross bracing of ultra-high voltage transmission tower[J].Journal of South China University of Technology(Natural Science Edition),47(7):19-31.(in Chinese)

- 钟岱辉,李荣帅,王文明.2020.输电塔—线体系灾变机理研究综述[J].四川建筑科学研究,46(3):37-45.

- Zhong D H,Li R S,Wang W M.2020.Review on disaster mechanism of transmission tower-line system[J].Sichuan Building Science,46(3):37-45.(in Chinese)

- Kitipornchai S.1996.Full scale testing of transmission and telecommunication towers using numerical simulation techniques[J].Advances in Steel Structures,12:43-53.

- Knight G,Santhakumar A R.1993.Joint effects on behavior of transmission towers[J].Journal of Structural Engineering,119(3):698-712.

- Soh C K,Chan T K,Yu S K.2000.Limit analysis of ultimate strength of tubular X-joints[J].Journal of Structural Engineering,126(7):790-797.